Foam Concrete Machine Foam Concrete Mixer Concrete Pump Machine

Calcium Stearate Emulsion

Anti Foaming Agent for Gypsum Defoaming Agent

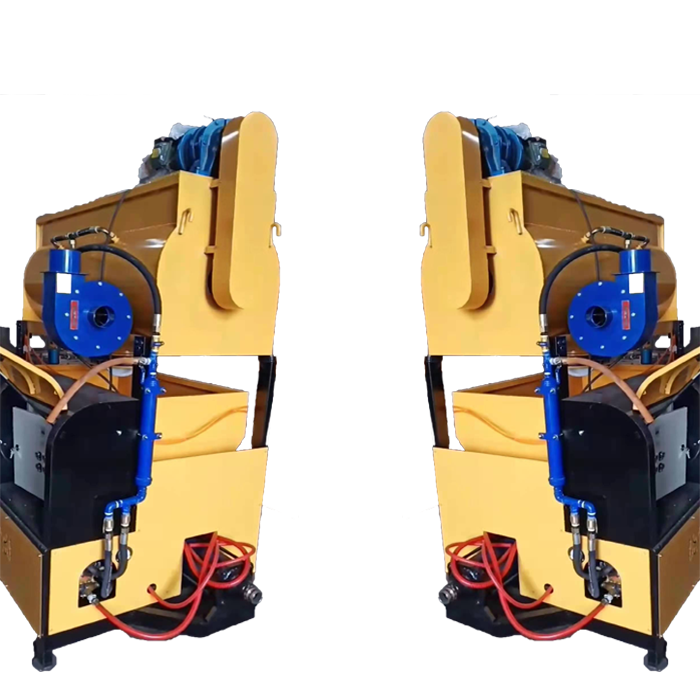

Automatic Foaming Concrete Intelligent Equipment for Cast-in-place Concrete

Foam Generator for CLC Concrete Foam Generator

Cellular Lightweight Concrete Foaming Agent Protein Foaming Agent

CLC Blocks are an eco-friendly and durable construction material that is used for building houses. They also have excellent sound insulation characteristics. In addition, they are also good for reducing electricity costs in summers and saving heating costs in winters. They are used in acoustic construction, precast exterior walls, low-cost housing and air-conditioned buildings. These blocks are produced by mixing slurry of fly ash, water and pre-formed stable foam. The mixture is then injected into moulds and the block cutter cuts them into different sizes. The foam concrete is then cured in an autoclave at a temperature of 180°C for 10 hours.

To make a clc block, the first mixture includes Portland cement, siliceous type class F fly ash, potable water and foaming agent (Techcell HT). The second mixture includes sawdust and sand. It is mixed with sufficient water to keep the relative moisture content in the range of 40% to 44%. This ensures that the grains of sand stick to the sawdust and prevents the finally produced blocks from cracking due to poor bonding of the cement.

The slurry is then injected into the molds and is vibrated, compressed, and cut with a blade to produce uniform blocks. A small amount of soap may be added to help remove the blocks from the molds and for easier removal after curing. The cured blocks are then stacked on pallets and rolled onto a conveyor for transport. They are then pushed from the pallets and the empty ones are fed back into the machine to set molded blocks.

Ask a quote for the latest price and one of our team members will respond as soon as possible. Fields marked with * are required.