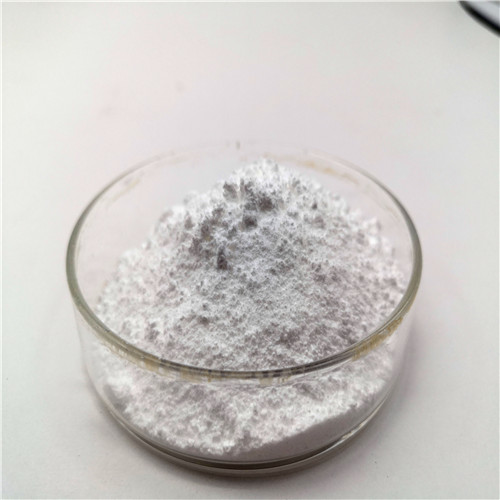

Cement Anti-crack Agent Preventing Cracks in Foam Concrete

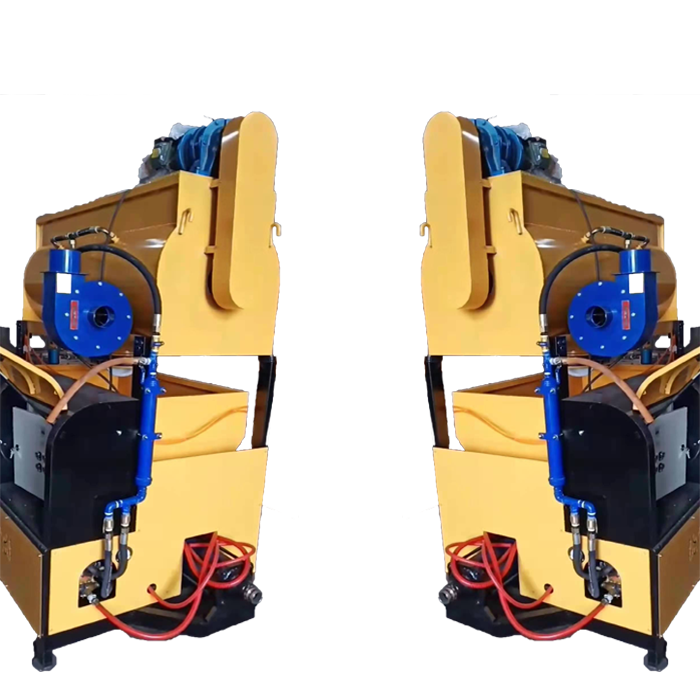

Automatic Foaming Concrete Intelligent Equipment for Cast-in-place Concrete

Gypsum Foaming Agent Protein Foaming Agent

Foam Concrete Machine Foam Concrete Mixer Concrete Pump Machine

Synthetic Foaming Agent for Concrete Cement Foaming Agent

Anti Foaming Agent for Gypsum Defoaming Agent

CLC blocks are much lighter than clay bricks and their density is only about 300 – 1800 kg/m3. The reason behind this light weight is the foam concrete that is used. Foam concrete has a low specific gravity as it entrains air within the cells. Moreover, it is also a very strong material due to the high compressive strength of the air bubbles.

To produce a foam concrete the cement/fly ash, sand and water is mixed together and then injected with pre-formed stable foam manufactured on site from TECHCELL HT. The foam concrete is then poured into moulds to produce the desired block size. It takes about 8 hours for the foam concrete to dry before it can be cut into blocks and used in construction.

foaming agent for clc blocks are usually made up of natural and synthetic based materials. These chemicals are used to make the cellular lightweight concrete (CLC) which is very commonly used in the construction sector. They have a wide range of uses as they are known to be very durable and economical to use. They also have a very low toxicity level and are eco-friendly. They are normally stored in their original containers and have a shelf-life of up to 2 years.

Previous research has shown that increasing the percentage of silica fume in the mortar mixture can increase the compressive strength of CLC. However, it is still unclear what the optimum amount of silica fume can be to achieve maximum CLC compressive strength. To find this out, a series of experiments and numerical analyses have been conducted to determine the displacement, stress and strain patterns for different amounts of silica fume substitution in the mortar mixture.

Ask a quote for the latest price and one of our team members will respond as soon as possible. Fields marked with * are required.